NEWS

Contact us

No.1,Jingang Road,Baini Town,Sanshui district of Foshan City,528100,Guangdong Province,China

No.1,Jingang Road,Baini Town,Sanshui district of Foshan City,528100,Guangdong Province,China

86-15916076335/86-13690463532

86-15916076335/86-13690463532

aimai113@fsaimai.com

aimai113@fsaimai.com

管理员|2019.11.16|Number of views:258

Light conveyor belt is one of the most important parts of belt conveyor, and the fastness of joint can almost determine the service life of conveyor belt. It is very painful when the conveyor belt is broken suddenly during using, not only cause the machine to stop production, but also the moment of disconnection will have a safety hazard. Therefore, it is particularly important to select the correct conveyor belt joints.

The following brief introduction of several light conveyor belt joint way from AIMAI industrial belt company:

Finger jointed endless

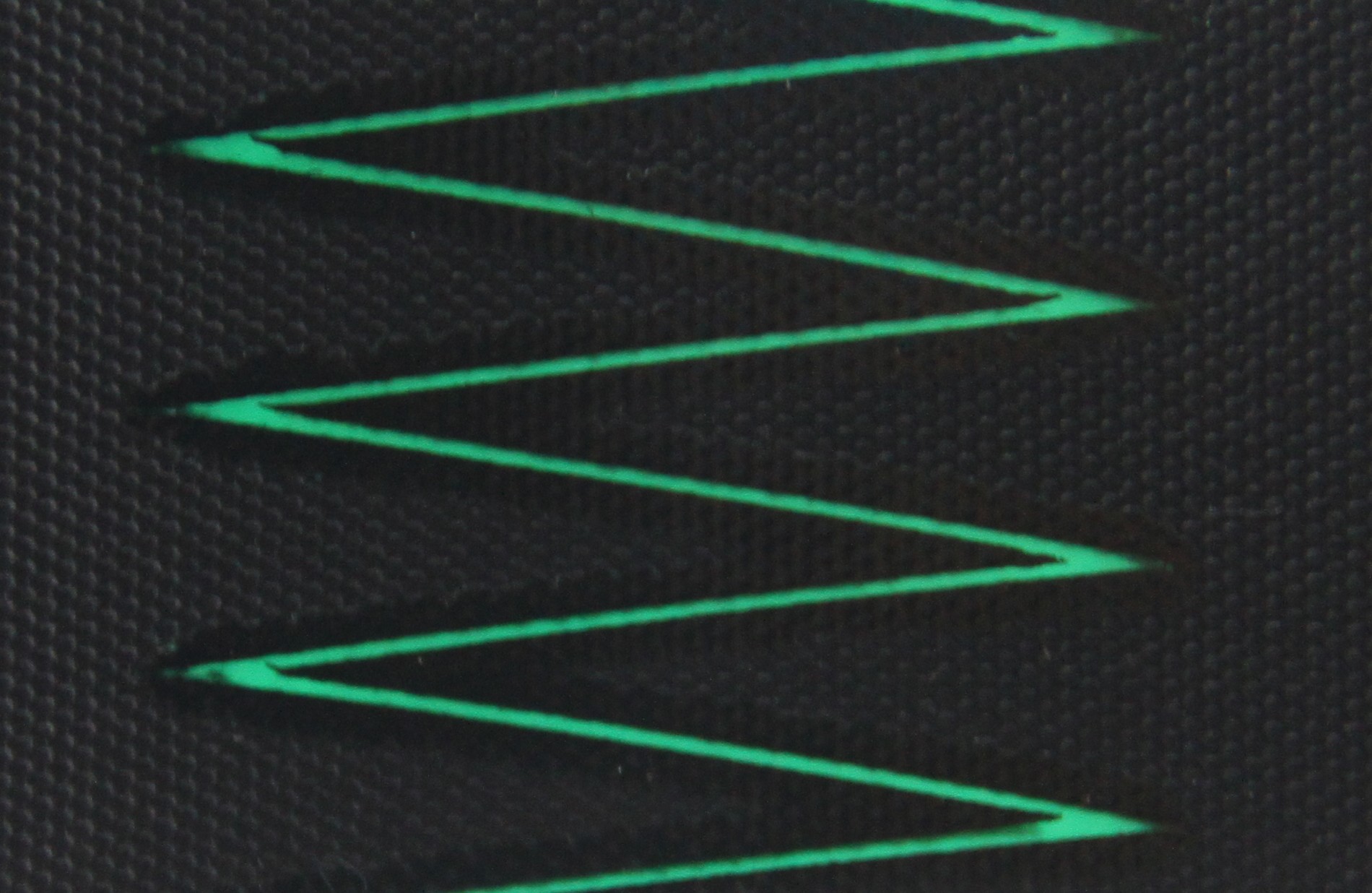

Finger joint is the most common joint mode of light conveyor belt, and it is also the most firm. Light conveyor belt first layering and then cutting, because the cutting shape like the finger, so called finger joint, finger joint is the international common joint. The finger joint is melting jointed together by high temperature vulcanization machine, the melted jointed parts is uniform, the thickness of the joint is consistent with the thickness of the belt, and the strength of the joint reaches about 90% of the rated tensile strength. The finger joint ensures the sanitary and easy-to-clean characteristics of the conveyor belt due to the high temperature fusion of the rubber surface.

2. Lap

In the case of inconvenient dis-assembly of the machine, you can choose to lap, which is also suitable for a special conveyor belt system. Lap joint is layered by the machine, and then after rough top grinding, with the given glue sent to customers, customers can be self-paste after receiving. The strength of the lap joint reaches about 75% of the rated tensile strength, and the thickness is consistent with the basic belt.

3. Steel buckle joint

The steel buckle joint is a kind of repeatedly detachable joint way, the steel buckle joint has advantages and disadvantages, the advantage is that it can effectively avoid the inconvenient installation after the conveyor belt is formed into a ring belt, the disadvantage is that it is not easy to clean, easy to breed bacteria, long service time easily lead to the conveyor belt joint slowly tear, short service life.

No matter which kind of joint you choose, Aimai reminds you to choose the right conveyor belt joint, not only can effectively increase the service life of the conveyor belt, but also improve the production efficiency.

The broken conveyor belt joint is mainly affected by the following factors:

1. The tension is too large, tension adjustment is too tight.

2. The conveyor exceeds the maximum load of the belt.

3. Running speed is too fast.

4. The conveyor belt is in a bad environment, aging accelerated;

5. Wrong selection of conveyor belt.

6. The conveying drum is too small, and the joint turns and does not fit the drum;

7. The conveyor belt runs for too long.

Not only to find the reason for the fracture of the conveyor belt joint, but also to maintain the conveyor belt, Aimai recommends you to choose the jointed mode reasonably, correct model selection, timely maintenance, beware of aging, timely replacement.

Contact:86-15916076335/86-13690463532

E-mail:aimai113@fsaimai.com

Copyright ©Foshan AIMAI Industrial Belt Co., Ltd